Products (3298)

Helping customers succeed requires more than supplying the iron. We provide consulting services on the front end to help you make the best equipment decision for your business and then help you optimize the value of your purchase with financing, technical service, and materials marketing services.

Consulting

Gathering and analyzing the information needed for a sound equipment business decision can be daunting when you consider all the variables...technology, applications, feedstock, material markets, people, and economics, to name a few. We take a side by side consultative approach to helping customers analyze their options on paper and providing a decision process. We call it the Impact Value Optimization Process (VOP) and our goal is to help customers narrow the gap between the value they believe they are purchasing, and the value they actually realize.

· Discover - problems and opportunities for improving your business

· Diagnose - the scope of problems/opportunities and their cost

· Design - a solution and define success

· Deliver - implement the solution and measure success

Financing

Once a purchase decision has been made, we can help find competitive financing from a number of sources. We can also provide options for physical damage insurance.

Technical Service

Machine downtime can increase hourly operating costs very quickly so keeping your equipment working is a key to your success. We can work with you to provide the level of technical support you need in a cost effective manner.

Materials Marketing

Processing materials from feedstock form to a valuable end product is the essence of recycling. Finding new markets and higher value uses for these end products is a constant challenge for recycling businesses. As part of our solutions based approach, we can help market the materials you produce with our equipment.

Wear Parts

Grinders · Screens · Hammers · Holders

Shredders · Knives · Spacers · Fingers · Screens

Crushers · Blow bars

Screening Plants · Screen cloth

Chippers · Knives · Drums

Mulchers · Teeth |

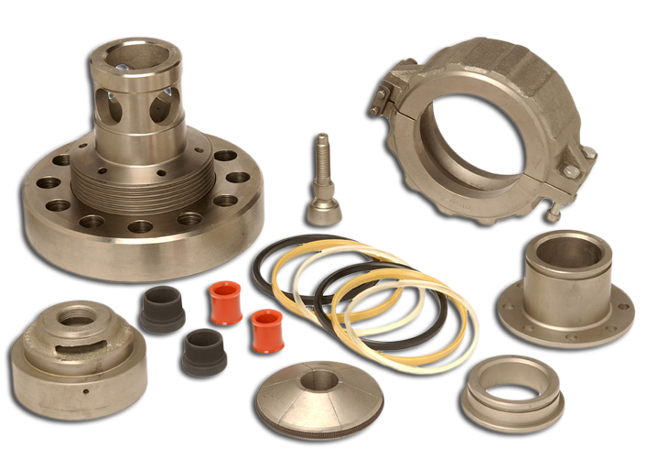

Service Parts

Engine Transmission Axle Gearbox Hydraulic Pump Hydraulic Motor Hydraulic Valve Hydraulic Cylinder Track Undercarriage Electrical Electronic Computer |

Maintenance Items

Filters Hydraulic Hoses Hydraulic Fittings Hardware Lubricants Batteries Seals O-rings

|

Buying Used Machines

If you are in the market for a used machine we welcome the opportunity to help you find the right fit for your business. Please browse our used machine selection by clicking on the appropriate machine type below. If you don’t see the right machine in our selection, please contact us and we will be happy to search our resources to help you find your machine.

Selling Used Machines

If you want to sell a used machine, we can help develop a remarketing plan to identify potential prospects, promote your machine, and assist in the sales process.

Used Machine Upgrades

Meeting your equipment needs does not always require a new, or different, machine. Sometimes the answer could be a lower cost upgrade to your existing machine like a specialized attachment, hydraulic controls, computer controls, or a package to include all the above. Talk with us about your goals and we can determine what is possible.

Remanufacturing

We strive to recognize and capture the value in equipment for our customers. If a machine has a solid core and structure, remanufacturing may be the best way to realize that value. Ask us about the potential to remanufacture your machine to include performance upgrades at a reasonable cost.

Mobile shredders from Badger are capable of processing all types of C&D material including wood and reinforced concrete. Impact can package mobile or stationary systems to include reduction, sorting, and handling for turn-key C&D systems.

EPS Foam Recycling Systems from RecycleTech reduce large quantities of loose foam scrap into dense ingots at a ratio of up to 90:1. This can reduce foam waste disposal costs by as much as 80%.

Glass Aggregate Systems makes complete systems for reduction and screening of bottles, full bottles, windshields, and plate glass. Labels, metal caps, and plastic caps are removed and separated in bottle systems. In windshield systems, laminate is separated and processed to a marketable form.

Forrec Tire Recycling Systems process car and truck tires into marketable end products including Tire Derived Fuel (TDF), various sizes of rubber granules, clean steel, and nylon fiber. Advanced air handling systems control rubber dust providing a clean, safe recycling operation. Systems can be implemented in phases allowing a recycling business to grow according to volume and end product needs while preserving capital.

A Screen Machine portable stacking conveyor is the perfect solution for any size operation. Being able to stockpile large amounts of material in high and wide piles without constantly repositioning your equipment is key to uninterrupted productivity. SMI's new 60' (18.3m) portable tracked conveyor is powered with a self-contained diesel module. Radial stacking conveyors are also available. Impact also represents the Titan Industries line of stationary conveyors and custom conveyors. Titan has a solution for any industrial application.

The Remu Big Float is a new type of machine for marshlands and shallow-water applications. It gets you to areas where traditional machines have never thought of going. The Big Float travels from the transport platform to the work site on its tracks - no hoists are required. The pontoons ensure the floatability of the machine in the water and safe travel on soft marshlands.

We offer optical sorters from Pellenc Selective Technologies that are designed to separate mixed waste streams like MSW, C&D, Industrial waste, E-Scrap, and End of Life Vehicles. Pellenc optical sorters can separate materials like plastic, paper, glass, wood, and metal by color or type of material.

Remu screening buckets fit all sizes of skid steer loaders, wheel loaders, and excavators. While Remu screening buckets shine in back filling and top soil applications, they can also handle difficult materials such as compost, mixed materials, demolition waste, clay, asphalt, and other sticky materials. Maximize your on-site capabilities by making a screening bucket part of an attachment system that includes quick couplers, crushing buckets, or other attachment tools.

Vibratory screening plants from Screen Machine are designed to screen aggregates, producing three different sizes of product simultaneously. Jobsite refuse such as wood, metal, plastic and more can be separated easily. Concrete and asphalt can also be recycled and reused. SMI's trommel screens are self-contained, diesel powered, track mounted portable screening plants designed to separate topsoil, compost and green waste type products.

Screen Machine Industries tracked impact & jaw crushing plants can be very useful tools in mining, aggregates, road building, demolition/recycling, and more. The waste generated from jobsites in many cases can be recycled, repurposed and reused to create other useful products and reduce landfill tipping fees.

Eco-Crusher rotary & jaw crushing buckets shine in on-site applications where volumes below 4,000 tons do not justify the mobilization expense of a large crushing plant. With models to fit skid steer loaders, wheel loaders, and excavators, you can utilize existing fleet machines that are already on the job. Maximize your on-site capabilities by making a crushing bucket part of an attachment system that includes quick couplers, screening buckets, or other attachment tools.

RecycleTech's EPS Foam Densifiers utilize high volume extrusion technology. Plastic foam scrap is placed into the hopper of the machine where it is crushed into small chunks. The pieces drop into an auger/screw where the material is heated and extruded into ingot for collection. The process is safe, clean and does not emit harmful emissions.

Glass Aggregate Systems offers a line of glass breakers with models ranging from .25 tons to 20 tons per hour. The glass breakers are typically used as part of a total glass recycling system, but can be utilized as stand-alone reductions machines also.

Granulators

Rotating blade granulators are used for grinding mixed plastic material waste produced in injection molding, extrusion, blow molding, and thermoforming. Forrec granulators are designed to provide maximum performance, energy savings, safety compliance, and minimal noise.

Sturdy, efficient and precise, single shaft grinders perform best in operations which require uniform control of output material dimensions. Equipped with interchangeable rotor plates and sizing screens, they are used in the management of any type of solid waste that does not contain large ferrous or metallic materials.

Shredders

Forrec stationary dual shaft shear shredders with counter-rotating shafts can be used for the reduction of any type of solid waste. They are the workhorse of the recycling industry. Impact also offers mobile track shredders from Badger that are designed to reduce the toughest materials like reinforced concrete, in addition to C&D waste, tires, and wood waste.

Eco-Crusher rotary & jaw crushing buckets shine in on-site applications where volumes below 4,000 tons do not justify the mobilization expense of a large crushing plant. With models to fit skid steer loaders, wheel loaders, and excavators, you can utilize existing fleet machines that are already on the job. Maximize your on-site capabilities by making a crushing bucket part of an attachment system that includes quick couplers, screening buckets, or other attachment tools.

Hydraulic kits include all components, instructions and support needed for complete installations of auxiliary hydraulic systems on excavators. Hydraulic kits specifically engineered for most excavator/attachment combinations with special attention given to optimizing attachment performance for the hydraulic flow and pressure supplied by the excavator.

Wedgelock quick couplers are designed with operator and site safety in mind. The Wedgelock 'Independent, Initial and Instant Safety System' or 'I-Lock' is the ultimate coupler back-up locking system available globally today. Attachment changes are completed safely and quickly without leaving the cab making the Wedgelock coupler the centerpiece of a multi attachment system.

Remu screening buckets fit all sizes of skid steer loaders, wheel loaders, and excavators. While Remu screening buckets shine in back filling and top soil applications, they can also handle difficult materials such as compost, mixed materials, demolition waste, clay, asphalt, and other sticky materials. Maximize your on-site capabilities by making a screening bucket part of an attachment system that includes quick couplers, crushing buckets, or other attachment tools.

The Remu Big Float is a new type of machine for marshlands and shallow-water applications. It gets you to areas where traditional machines have never thought of going. The Big Float travels from the transport platform to the work site on its tracks - no hoists are required. The pontoons ensure the floatability of the machine in the water and safe travel on soft marshlands.